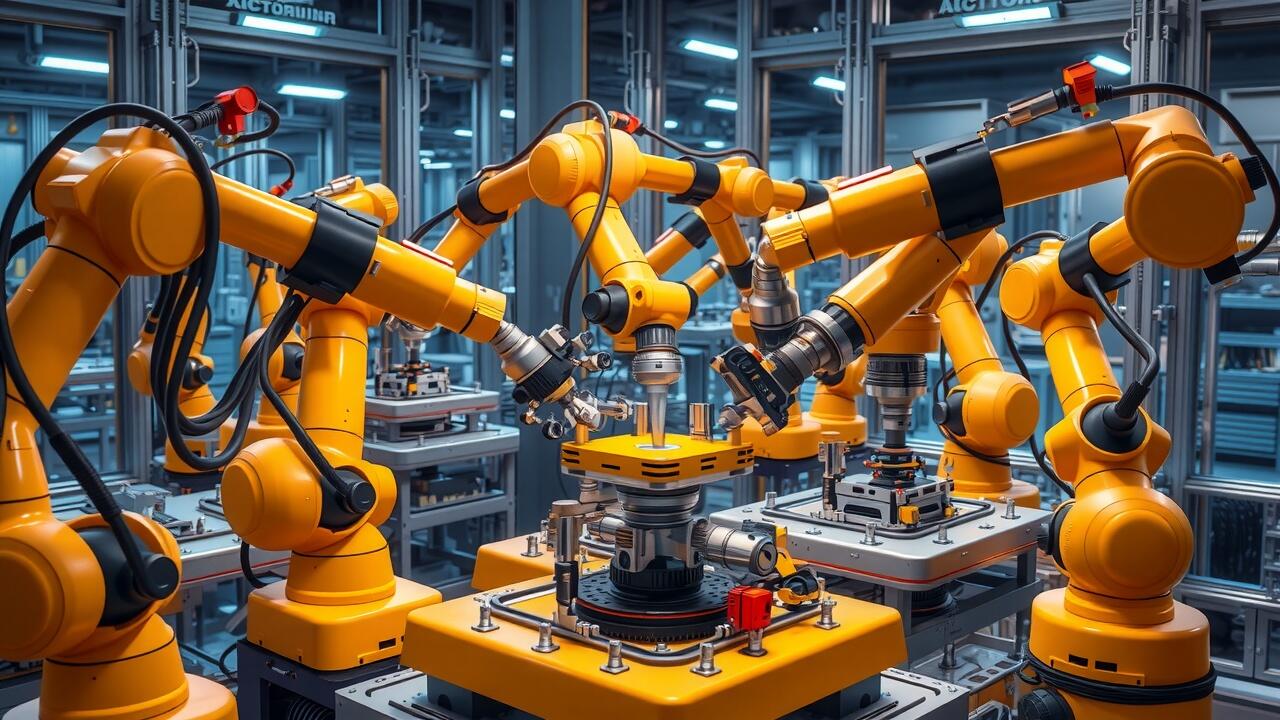

How Fixture Design Impacts Cycle Time in Robotic Assembly Cells

Table Of Contents

Key Takeaways

- Examining how testing fixtures affects duration in robotic assembly

- Selecting between tailored and conventional fixtures for optimal performance

- Merging technology with fixture creation for better efficiency

- Considering ergonomic factors in the design of fixtures for improved usability

Analyzing the Impact of Fixture Testing on Cycle Time

Fixture testing plays a crucial role in optimizing cycle time within robotic assembly cells. When teams invest time in rigorous testing, they can identify inefficiencies early on. For instance, a manufacturer specializing in high quality assembly fixtures found that thorough validation reduced assembly time by 20%. This reduction can be attributed to adjustments made during the testing phase, where issues like misalignments were easily spotted and rectified before full-scale production.

The use of performance metrics during fixture testing enables teams to create data-driven improvements. By analyzing cycle times, teams can pinpoint which aspects of the manufacturing assembly fixture need refinement. A case study from a leading automotive manufacturer showed a direct correlation between optimized fixture design and a 15% increase in throughput. Engaging in fixture testing not only minimizes delays but also enhances overall productivity, ensuring that the final product meets both quality and efficiency standards.

How Can Testing Improve Fixture Performance? (highlighting methods for validation and adjustment)

Testing fixtures is essential in enhancing their performance within robotic assembly operations. For instance, employing simulation software can predict how different designs will interact with components during assembly. This approach allows teams to fine-tune their designs before physical implementation, potentially reducing cycle time by as much as 20%. Testing under various conditions ensures that high-quality assembly fixtures maintain accuracy and efficiency, leading to consistent production outcomes.

Another valuable method is conducting stress and load testing to validate the durability and reliability of manufacturing assembly fixtures. By gathering data on how fixtures respond to operational loads, engineers can identify weaknesses and make necessary adjustments. Some companies have reported significant decreases in downtime after implementing modifications based on systematic testing results. A solid plan for fixture testing not only secures improved productivity but also provides accurate manufacturing assembly fixture quotes for budgeting purposes.

| Testing Method | Description | Benefits |

|---|---|---|

| Simulation Software | Predicts interactions of design with components. | Reduces cycle time by up to 20%. |

| Stress Testing | Evaluates durability under operational loads. | Identifies weaknesses and prevents downtime. |

| Load Testing | Assesses performance under heavy loads. | Ensures fixtures maintain accuracy and efficiency. |

| Environmental Testing | Examines fixture behavior in varying conditions. | Enhances reliability in different environments. |

Custom vs. Standard Fixtures

When deciding between custom and standard fixtures, consider the specific needs of your assembly process. Standard fixtures offer cost-effectiveness and can be readily available, making them a good option for straightforward applications. For instance, in a high-volume manufacturing environment, a standard manufacturing assembly fixture might streamline operations without the lengthy design cycle that custom options require. This approach can significantly reduce lead times, allowing production to kick off more quickly than custom solutions.

On the flip side, custom fixtures shine when dealing with specialized tasks or complex components. For example, a manufacturer involved in delicate electronics assembly often requires high quality assembly fixtures designed precisely for their products' unique shapes and tolerances. Custom fixtures provide that level of specificity, ensuring a consistent and reliable fit that standard fixtures might not achieve. Ultimately, businesses should weigh the implications of each type against their production goals to determine the most efficient path forward.

When Should You Opt for Custom Fixtures? (evaluating cost, flexibility, and specific needs)

Choosing between custom and standard fixtures often boils down to specific application needs. If a product has unique features or complex geometries, custom assembly fixtures can provide a perfect fit that standard options simply can't match. For instance, a manufacturer producing intricate automotive parts may require fixtures designed to accommodate varying tolerances. Custom designs can improve the accuracy of assembly processes, leading to a reduction in errors and rework. The upfront investment in manufacturing assembly fixture quotes may seem daunting, but the long-term benefits of enhanced productivity and decreased cycle times often justify that expense.

Flexibility is another key reason to consider custom fixtures. When production requirements evolve, these fixtures can be reconfigured or adapted more easily than their standard counterparts. For example, a high-quality assembly fixture designed for a specific product line can often be modified to accommodate new variations or completely different products. By keeping the same base design, companies can minimize downtime and streamline transitions to new projects. Taking this approach can save time and labor costs, reflecting a strategic advantage in fast-paced manufacturing environments.

Integrating Technology in Fixture Design

Smart integration of technology in fixture design elevates the performance of manufacturing assembly fixtures significantly. For instance, using advanced sensors helps gather real-time data on equipment performance and product quality. This means manufacturers can quickly identify problems that might slow down production. Companies leveraging this tech saw cycle time decreases between 15 to 25 percent, showcasing the tangible benefits of embedding technology into fixture systems. By optimizing fixture design through automation, teams can streamline operations while maintaining high standards.

Adopting software platforms for fixture design also simplifies the process of creating custom solutions. Upfront cost considerations often discourage investments in high-quality assembly fixtures, but the long-term efficiencies can outweigh these initial expenses. A case study demonstrated that a manufacturer who utilized design simulation software was able to tweak their fixture within hours, rather than days. By cross-referencing manufacturing assembly fixture quotes, companies can benchmark their investments against industry standards, ensuring they make informed choices that benefit their operational efficiency and productivity.

How Does Automation Affect Fixture Development? (looking at software, sensors, and data analysis)

Automation has a significant role in developing advanced manufacturing assembly fixtures. The incorporation of sensors allows for real-time monitoring, and data collection enhances quality control throughout the assembly process. For instance, using pressure sensors can ensure that components are securely fastened before moving on to the next step. This real-time feedback loop reduces errors and contributes to the overall efficiency of the production line. Additionally, software integration for predictive analysis helps identify potential failures and optimize fixture design before any physical alterations are made.

Moreover, automation tools enable manufacturers to generate high-quality assembly fixtures tailored to specific operational requirements. For example, digital twins can simulate the assembly process, allowing engineers to experiment with modifications in a virtual environment before any tangible resources are allocated. This proactive approach not only lowers costs but also ensures that fixtures meet design specifications while enhancing cycle times. Collecting and analyzing data from these automated setups facilitates continuous improvement, where adjustments can be made based on performance analytics, helping manufacturers refine their processes and maximize productivity.

The Influence of Ergonomics on Fixture Design

A well-designed fixture ensures that operators can access all components comfortably, minimizing strain during repetitive tasks. Ergonomic principles suggest that maintaining proper body posture helps reduce fatigue and error rates, crucial for maintaining high efficiency in robotic assembly cells. For instance, a study confirmed that fixtures allowing for adjustable heights resulted in a 20% decrease in overall assembly time. A careful alignment of tools and workpieces can further enhance workflow and promote a faster cycle time.

When integrating ergonomic considerations into fixture design, analyze the specific needs of the operators involved. This includes evaluating reach distances, angles for tool use, and the overall environmental setup of the workstation. High-quality assembly fixtures, designed with feedback from workers, can lead to a significant reduction in workplace injuries and enhance productivity. If a manufacturing assembly fixture does not account for ergonomic factors, it could result in costly delays and inefficiencies on the production line. Prioritizing ergonomics in fixture design not only promotes operator safety but also translates to better performance metrics across assembly tasks.

FAQS

What is a fixture in robotic assembly?

A fixture is a device used to securely hold and position parts during the assembly process, ensuring precision and efficiency in robotic operations.

How does fixture design affect cycle time in robotic assembly?

Well-designed fixtures can streamline the assembly process by reducing the time needed for part placement and adjustment, leading to faster overall production cycles.

What are some methods for testing fixture performance?

Common methods include using simulation software, conducting physical tests, and analyzing cycle time data to identify areas for improvement and make necessary adjustments.

When should I consider using custom fixtures instead of standard ones?

If your assembly process has unique requirements, needs specific tolerances, or requires flexibility that standard fixtures can't provide, custom fixtures might be the way to go.

How can technology enhance fixture design?

Integrating technology like automation, sensors, and data analysis can improve fixture design by providing real-time feedback and optimizing the performance of robotic assembly cells.

What role does ergonomics play in fixture design?

Ergonomics is crucial as it ensures that fixtures are designed for ease of use and safety, which can improve operator efficiency and reduce the risk of workplace injuries.